With over 20 years of experience in Defense, Aerospace, Automotive, Industrial Equipment, and Energy sectors, we support your digitalization and rapid production journey. Our Industrial Metal 3D Printers and Additive Manufacturing technologies, suitable for serial production, enable innovative designs, strategic product development, and fast, flexible production to boost efficiency. As your trusted partner in 3D Digital Transformation, we enhance customer experience, ensure a competitive work environment, enable quick adaptation to changes, and increase profitability. With tailored solutions and success stories, we are ready to contribute to your sustainable growth.

SLM 280 2.0 is the ideal 3D Metal printer designed for prototyping and medium/high volume production of parts, especially thanks to its multi-laser and closed-loop powder processing capabilities. With its 280 x 280 x 365 mm manufacturing area and Multi-laser (dual) feature, it can work with countless different types of materials. The system, which is completely flexible in terms of material supply, is open source and has no material dependency.

The first four-laser system in its field, the SLM 500, can be integrated with lasers to work independently or in parallel to produce up to 90% faster than dual-laser systems. - 500 x 280 x 365 mm manufacturing area - Multiple lasers (dual or quad) - Special material - Automatic powder processing - Turnkey solution with part removal station With its 500 x 280 x 365 mm manufacturing area and Multiple laser (dual) feature, it can work with countless different types of materials. The system, which is completely flexible in terms of material supply, is open source and has no material dependency.

The SLM®125 is a 3D Metal printer designed to meet your prototyping, low-volume production, mass production for small-sized parts, and R&D needs. - 125 x 125 x 125 mm manufacturing area - Single laser - Multi-material With a 125 x 125 x 125 mm manufacturing area, it can work with countless different types of materials. The system, which is completely flexible in terms of material supply, is open source and has no material dependency.

The SLM®800 features an extended Z-axis for large-scale production, and the ability to connect multiple machines via the SLM HUB® opens up new possibilities for mass production. - 500 x 280 x 850 mm build area - Multi-laser (quadruple) - Permanent filter - Multi-machine setup - SLM HUB® automatic cylinder transport and dust management With a 500 x 280 x 850 mm build area and Multi-laser (dual) capability, it can handle countless different types of materials. The system is completely flexible in terms of material supply, is open source and has no material dependencies.

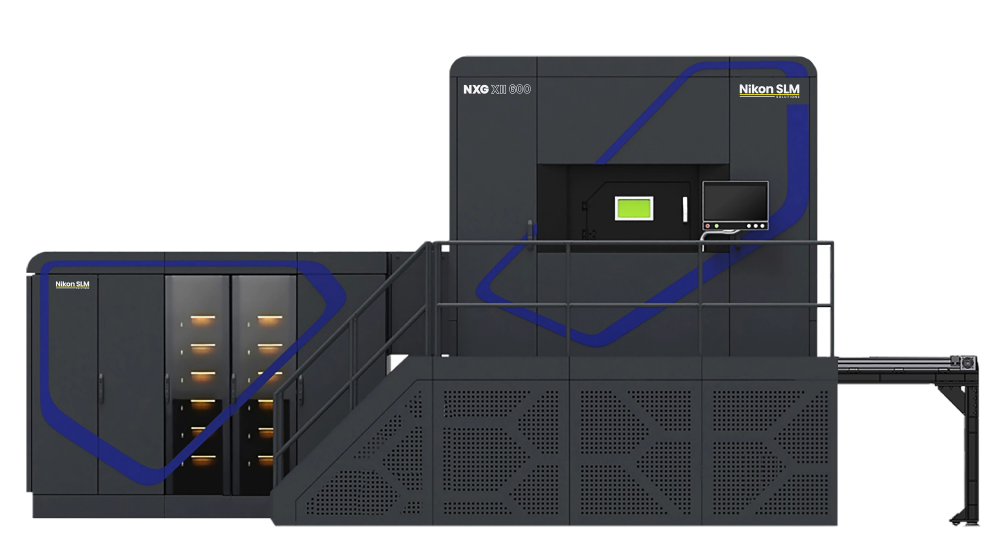

The NXG XII 600 is the world’s first patented 12-laser system capable of producing 600 x 600 x 600 mm parts in one run for large-scale production, and the ability to connect multiple machines via the SLM HUB® opens up new possibilities for mass production. - 600 x 600 x 600 mm manufacturing area - 12 lasers - Multiple lasers - Permanent filter - Multi-machine setup - SLM HUB® automatic cylinder transport and dust management With a 600 x 600 x 600 mm manufacturing area and 12 lasers, it can handle a myriad of different types of materials. The system is completely flexible in terms of material supply, is open source and has no material dependency.

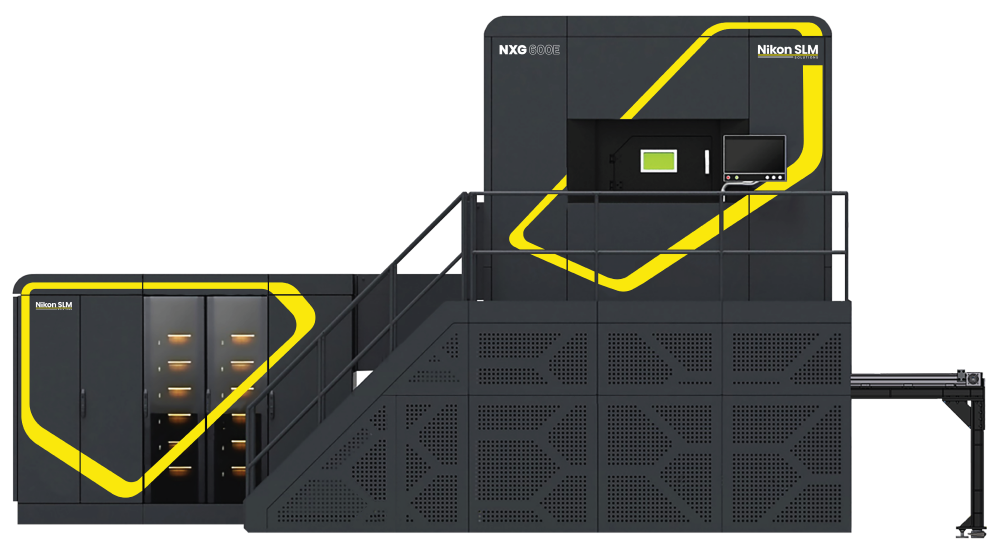

The NXG 600E is the world’s first patented 12-laser system capable of producing 600 x 600 x 1500 mm parts in one run for large-scale production, and the ability to connect multiple machines via the SLM HUB® opens up new possibilities for mass production. - 600 x 600 x 1500 mm manufacturing area - 12 lasers - Multiple lasers - Permanent filter - Multi-machine setup - SLM HUB® automatic cylinder transport and dust management With a 600 x 600 x 1500 mm manufacturing area and 12 lasers, it can handle a myriad of different types of materials. The system is completely flexible in terms of material supply, is open source and has no material dependency.